Next steps after Paris workshop in February 2018 :

Here is an excerpt from our last research note to contextualize this work and explain why we are moving from a rigid plastic color for the structure of the netting to a fabric-based design:

As we were packing up [after a workshop in Paris], Garance Marville, coalesced some of the problems noted above into a potential way forward. As the plastic collar seemed to create as many problems as it addressed, perhaps an all fabric version---eliminated the need for rigid plastic--is the next step. A fabric version made with elastic or neoprene, would be lighter (cheaper shipping), malleable shape for many shipping options, more easily reparable, and require less expensive/specialized technology for production. We could also potentially ship the sewing patterns (my great grandfather was in the sewing pattern business) so that the DIY version and the commercial version were not so dissimilar from each other.

(c) Christophe GUERIN

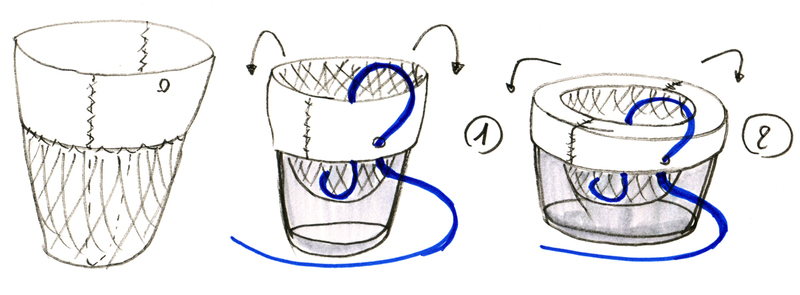

New adjustable design :1 - Small pot ; 2 - Large pot

New Design:

- A basket made of two materials.

The top of the basket will be made of neoprene. This flexible material will enable the basket to adjust to different size pots. There will be one hole, close to the top, in order to pass the tube through the neoprene and maintain the tube in the correct position under the root ball. The second part of the basket will be mesh, that will allow water to freely flow through but retain the growth medium and the weight of the medium and the plant, if the whole basket needs to be removed for maintenance. - A plastic tube.

- Hydroculture growth medium and activated charcoal.

- A container (to be supplied by user).

- A plant from our list (to be supplied by user).

March - April - May 2018

I started doing materials research for a fabric-based prototype. I was looking for a 3D knitted material and a neoprene. I was interested in synthetic materials in order to minimize water absorption.

Photo : (c) Christophe GUERIN

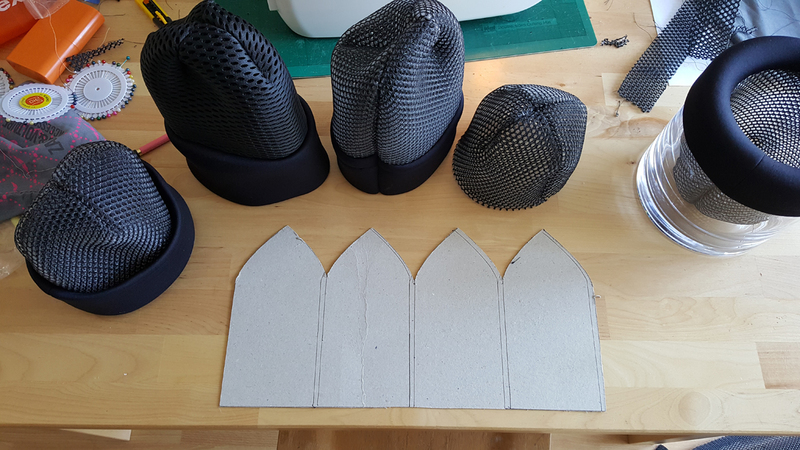

I ordered few options of both materials and started to make prototypes. I designed a simple cut pattern to help me cut the fabric and sew them altogether.

To make it simpler and faster, I choose to work on the small size pot, with a diameter of 13 cm (~5.1 inches). I bought a glass container with a diameter of 15 cm (~5.9 inches).

Photo : (c) Christophe GUERIN

Second prototype I did : A simple shape, elegant and with a soft feel. To be able to improve the finish of the seam I had to roll it then return it. The finish is as I would like it now but I don't know how to fix the plastic tube. (c) Christophe GUERIN

June 2018

After doing many tests on my own, using a non-professional sewing machine, I went to arts décoratif morpho structure department and used a professional machine. As my materials are synthetic, I was sure that I could use an ultrasound machine, which melts the materials together.

Photos : (c) Christophe GUERIN

Indeed it worked, but the welding became rigid and it was difficult to have a nice and soft shape. To remedy this situation I found a second ultrasound machine in the textile department, smaller than the first one. It allows for more maneuverability in how you cut and weld the material together as it is more of a hand tool than a large industrial machine. It could be useful, for making nice finished edges or to cut specific shape. It could also be the right tool to make a hole in the neoprene to fix the plastic tube.

Photo : (c) Christophe GUERIN

July 2018

First materials I bought were not good enough. It wasn't a real neoprene material, so I looked for a better one in Germany. I found new products and bought them for the next prototype series.

Photo : (c) Christophe GUERIN

This time, I designed 3 pot sizes: 21 cm diameter, 17 cm and 13 cm.

I did new cut patterns, using 4 modules and six modules. The more you have facets and softer / rounder your pots will look like.

4_modules_-_13_cm_diameter.pdf

4_modules_-_17_cm_diameter.pdf

4_modules_-_21_cm_diameter.pdf

6_modules_-_17_cm_diameter.pdf6_modules_-_21_cm_diameter.pdf

Photo : (c) Christophe GUERIN

I chose to work only with black colour, but for the next series, I could select a range of colours.

I also need to improve the edges finishes.

Photo : (c) Christophe GUERIN

Next steps

I want to worked with a garment professional expert, and asked him or her, to improve the finishes. We need to make a perfect hole for the plastic tube. In addition, we need to improve the edge finishes. I will select few colours to make new combination, like dark green / black, light pink / blue, Brown and yellow...

New Technic / Process

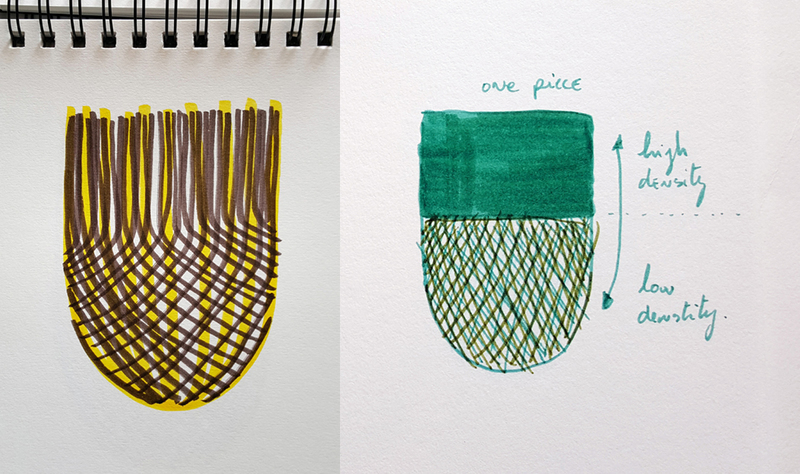

I want to worked with a company doing tricotin, 3D mesh / digital mesh computing. I would like to produce the net in one piece. I don't know exactly how I will make it neither what it will look like, but I have ideas and I know good companies.

I would love to mix different kind of thread, mixing colours and giving it a technical shape and aesthetic like new running shoes products.

Image : (c) Christophe GUERIN

Lastly, but importantly, I want to start mixing flower pots and algae, working altogether to purify the air.

I must find the right algae species, matching with the right plants.

Photo : (c) Christophe GUERIN

1 Comments

Built one of these at a recent Barnraising!!! https://publiclab.org/notes/warren/10-25-2018/building-a-plant-based-air-purifier-kit-at-barnraising

Reply to this comment...

Log in to comment

Login to comment.